For many years now forms of metal bearings are what have been the standard for many industries; the use of plastic bearings however is something that is steadily on the increase. For example plastic bearings are now the main choice when it comes to the food industry and this comes with good reason�

Due to the fact that plastic bearings are excellent in wet and corrosive environments as well as clean environments that are difficult to lubricate, they become the ideal bearing to be used in a variety of machinery and applications that are associated with the food industry. Below are a few examples of some of the aspects that plastic bearings feature in when it comes to the food industry:

�Bakeries use them within their machinery

�They feature within beef, pork, poultry and fish processing

�Beverage bottling

�Dairies require them to complete jobs

�They are used within fruit and vegetable processing

�Lastly they feature within packaging and processing

When plastic bearings are used within such aspects of the food industry they are subjected to some rather harsh conditions, which includes daily high pressure wash downs, moist environments and contact with antibacterial cleansing solutions. The thing about plastic bearings however is they can handle such conditions. They are corrosion resistant and non magnetic. It is thanks to the huge increase in plastic technology that the use of plastic bearings within the food industry has become commonplace. Plastic bearings are now one of the more popular choices when used in the food industry. Although stainless steel ones are still widely used and will continue to be but the advantages of plastic ones are very clear.

Plastic bearings are well suited for any stage of the processing cycle, from the front end where weight and impact are the primary concern through to the ready to eat components where corrosion resistance is critical. Unlike other bearings, these ones are designed to withstand a variety of tough working conditions, which includes dirty, dusty and contaminated environments.

Another reason as to why plastic bearings are becoming the chosen choice within the food industry comes from a manufacturing point of view, which is that the plastic can be moulded into what seems to be an unlimited number of different bearing formats in order to fulfil particular requirements.

Within the food and drink industry, the bearings that are used need to be able to perform to the highest degree of reliability with exposure to food particles and while being subjected to continual cleaning. This is so important as hygiene and safety are of the same importance as efficiency and production within this industry, which is where plastic bearings can help. These bearings are made from a variety of plastic materials and are often self lubricating, which is another helpful perk as it allows smooth operation and a greater durability.

If you are involved in the food and drink industry you will have probably started to notice that the advantages associated with plastic bearings are pretty much limitless. So lets recap; they are corrosion and chemical resistant, have a reduced weight, low friction and provide whole system cost reductions. With all of this in mind, my advice to you is to invest in plastic bearings for all of your food and drink industry needs!

Introduction To Of Some Lower Cholesterol Foodstuffs

Cholesterol is a fat-like element contained in the physique

Introduction To Of Some Lower Cholesterol Foodstuffs

Cholesterol is a fat-like element contained in the physique

The Simplest Way To Lessen Your High Cholesterol By Natural Means

High-cholesterol is a major variable inside the countrywide

The Simplest Way To Lessen Your High Cholesterol By Natural Means

High-cholesterol is a major variable inside the countrywide

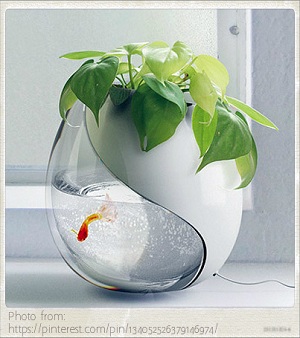

Starting Up An Aquaponics Set Up From See The Easy Way

Planting seeds in your aquaponics system can be a lot simpl

Starting Up An Aquaponics Set Up From See The Easy Way

Planting seeds in your aquaponics system can be a lot simpl